Products

PRINCIPLE OF REVERSE OSMOSIS SYSTEM

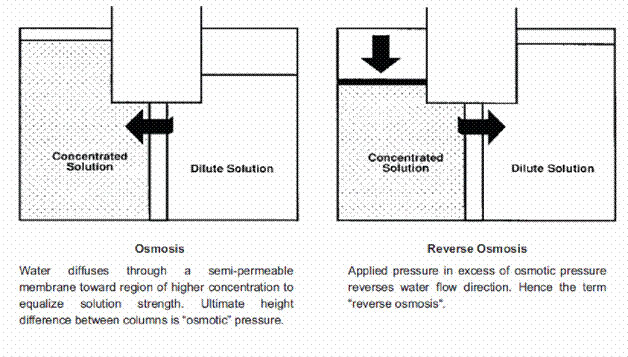

When a semi permeable membrane separates a dilute and concentrated solution of salts, due to osmosis, the water from the dilute solution side passes though the membrane to the concentrated side till osmotic equilibrium is attained. Now, if the pressure is applied and increased gradually on the concentrated side, the flow of water continues to reduce till the applied pressure is equal to the osmotic pressure. Any pressure in excess of the osmotic pressure reverses the direction of flow of water and water from the concentrated side enters the dilute side. This process is called the Reverse Osmosis. It is very essential to ensure that the water fed to reverse osmosis membranes is free from particulate matter, scale-forming salts of Ca & Mg and silica to prevent membrane fouling, scaling. Also the water should be free from organic matter, oil & grease, heavy metals and oxidizing agents like free chlorine.

The purest form of membrane technology is reverse osmosis. This process removes 95% or more of the salts dissolved in the incoming water. Almost all organic molecules with a molecular mass of more than 100 g/mol are retained by the membrane. Only the water molecules can pass through the membrane, and these form the product output.

Reverse Osmosis Unit:

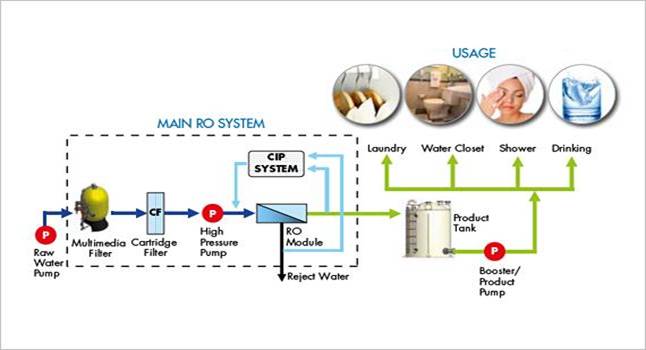

The Reverse Osmosis Unit comprises a high-pressure pump, pressure tubes and membranes as the main components. The high-pressure pump boosts the feed water to a pressure required to desalinate the water. The permeate quantity (recovery %) is designed as per system design software as per membrane manufacturer’s recommendations and with our experience to achieve the optimum advantage like maximum life and less cleaning for membranes. The concentrate/reject water from RO system is disposed to drain or can be reused/recycled further for eliminating water waste.

The Reverse Osmosis skids are fully assembled, tested and only then shipped to site. This ensures that no detailed assembly or erection work has to be carried out at site on the Reverse Osmosis systems.

The skid design, installation, operation and maintenance is backed by our experience in supplying such systems in India and abroad and we are also pleased to inform you that we have the many number of Reverse Osmosis installations in the country today.

We have ensured by proper selection only the right components are used in the assembly of the Reverse Osmosis systems.

The major components are:

- High Pressure Pump

- Pressure tubes

- Membranes

- Cartridge filter assembly with cartridge

- Sample valves

- Pressure Switches

- Skids

- Flow meters

- High & Low Pressure Pipelines

This system removes dissolved solids by the principle of “Reverse Osmosis Process” at the rejection rate of 95 – 99% w.r.t. specific ions in feed water. This system consists of an epoxy painted structural steel skid for mounting of high pressure tubes with spiral wound membrane elements for each stream. Necessary control valves are provided with required instrumentation for operating & performing parameters.

Pressure gauges are provided for pressure indication and control of complete R.O. System. Online /bypass types of flow indicator at product & brine pipe work are provided for controlling feed flow rate & recovery. For monitoring product water quality online conductivity indicator is provided.